| >> Japanese | |

|  |

|

■ Contact・・・CEO Soichiro Nakatsuka ■ Phone・・・・・Phone.+81-86-472-2709 FAX.+81-86-472-2700 | |

| Carburizing of pins and rollers and gas nitriding before grinding and finishing |

| ■PR movie is seen.■ |

【Technology and Product】

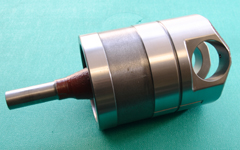

【Technology and Product】Due to the machining line composition, we mainly process cylinder-shaped products, however, our system is suitable for machining of various thicknesses. We specialize in grinding and finishing after carburizing the pins and rollers and gas nitriding. In addition to the machining, we are capable of simple unit assembling.

Grinding and honing of inside and outside of product

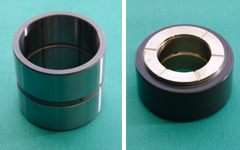

We have sufficient experience in achieving the best combination of products requiring accurate fitting by grinding, honing, and lapping.

Grinding and finishing

Not only are we experienced in the grinding and finishing (Ra 0.2 or better) of highly hardened products after carburizing and gas nitriding, we also have sufficient experience in manufacturing FCD roller bearing guides which can satisfy customer needs.

■ Advantages

■ AdvantagesManual fine tuning of dimensions and improvement of surface roughness

■ Range of application

1.Aircraft components

2.Engine components for ships

3.Components for general industrial machine tools

■ Processing accuracy

Dimension:10μ〜2μ

Roughness: about 〜Ra0.1

■ Material availability

Special metals after surface treatment, Cu alloy, FC, FCD, etc.

|  |

【Company Profile】

【Company Profile】| ■ Company Name | : | Nakatsuka Iron Works Co., Ltd |

| ■ Representative | : | CEO Soichiro Nakatsuka |

| ■ Address | : | 〒711-0917 2-7-29 Ajino-kami, Kojima, Kurashiki, Japan |

| ■ Establishment | : | Dec. 1920 |

| ■ Capital | : | 10 million yen |

| ■ Employees | : | 9 |

| ■ Major products | : | Cutting, milling, and grinding of components for fuel pumps and engines, as well as surface treated components |

| ■ Web site URL | : | http://www.nakatsuka.net/ |

|  |

|

Nakatsuka Iron Works Co., Ltd. |

Major Equipment |