| >> Japanese | |

|  |

|

■ Contact・・・GM of Okayama Office Isamu Kanchiku ■ Phone・・・・・Phone.+81-868-72-3901 FAX.+81-868-72-4871 E-Mail: okayama@nakaseiki.co.jp | |

| Only one piece, small lot, and large lot. We, a unique company of precise machining, have been delivering satisfaction to our customers. Quality products are the satisfaction of customers, and thus, we continue our efforts in creating such products. |

| ■PR movie is seen.■ |

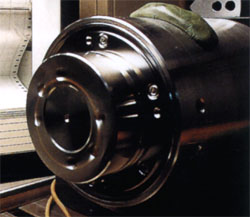

State-of-the-art riveting and forming technologies (radial riveting)

Our unique technologies actualized the extra-precise riveting of various materials and parts which used to be difficult to rivet.

Our unique technologies actualized the extra-precise riveting of various materials and parts which used to be difficult to rivet.■ Advantages

The pressure given to punch will move the punch down and press the rivet slightly. This motion is repeated for several thousand times in a second so that even riveting with good appearance and no structural issues can be achieved. This process is suitable for the riveting of 1mm or less, part forming which requires high quality, and plastic riveting.

■ Range of application

Automotive and aircraft parts manufacturing (brake, airbag, steering link, plastic processing, etc.)

■ Processing accuracy

0.01mm

■ Material availability

Stainless, die-cast metal, titanium, hard aluminum, polycarbonate, etc.

We will supply parts which are required the microscopic accuracy and absolute reliability.

"Precision" and "mass production" often conflict. However, we strived to create volume-production machinery and tools which are essential to the actualization of both "precision" and "mass production" as our keywords are "flexible" and "creative". Now, our long accumulated know-how was highly valued.

"Precision" and "mass production" often conflict. However, we strived to create volume-production machinery and tools which are essential to the actualization of both "precision" and "mass production" as our keywords are "flexible" and "creative". Now, our long accumulated know-how was highly valued.■ Advantages

Introduction of highly accurate machines, training offered to be skilled operator, and production control based on IT systems are our tools to improve our production technologies. We ensure to meet customers' expectations by supplying extra precise and fine parts with absolutely reliable quality.

■ Range of application

Computer components, VTR components, DVD/CD-RW pickup parts, AV machine components, various prototypes, airbag parts, grinding, spindle for machine tools, fixtures, and cutting tools (crescentic reamer, etc.)

■ Processing accuracy

0.001mm

■ Material availability

Aluminum, aluminum die-cast, stainless, aluminum allow with high content of silicon, titanium, magnesium

【Company Profile】

【Company Profile】| ■ Company Name | : | Nakaseiki Co., Ltd. Okayama Factory |

| ■ Representative | : | Plant GM Tatsumi Kanda |

| ■ Address | : | 〒707-0043 33 Miuchi, Mimasaka, Okayama, Japan |

| ■ Establishment | : | 1952 |

| ■ Capital | : | 20 million yen |

| ■ Employees | : | 70 |

| ■ Major products | : | (1) Machining parts, such as computer components, VTR components, airbag parts, and spindle of machine tools. (2) Original products: Air chuck, hand press machine, precise rivet machine, air hammer, tooling fixtures, etc. |

| ■ Remarks | : | IS09001 Certified in June, 2001 IS014001 Certified in February, 2005 |

| ■ Web site URL | : | http://www.nakaseiki.co.jp/ |

|

Nakaseiki Co., Ltd. |

Major Equipment |