| >> Japanese | |

|  |

|

■ Contact・・・GM Shozo Miyake ■ Phone・・・・・Phone.+81-86-952-2121 FAX.+81-86-952-4120 E-Mail: Hikari-eigyou@ph4.harenet.ne.jp | |

| We fulfill all of our customers’ requests speedily from the prototype making to the serial production of aluminum casting |

| ■PR movie is seen.■ |

【Technology and Product】

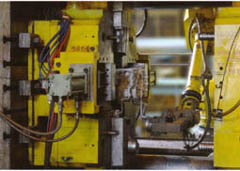

【Technology and Product】Die casting

In the past, the blowhole was a major disadvantage of die-casting. However, localized squeeze casting solved this blowhole issue and blowholes are not produced even when pouring molten metal at high-speeds. Heat treatable pressure-proofed and high strength components and components with even thinner walls can also be manufactured using this casting method. Currently, we have 10 die casting machines in total and are able to cast products in a variety of sizes using these casting machines. At the same time, we promote “Single changeover” which means to change molds within 10 minutes so that we are able to manufacture products in small lots with a short lead-time quickly upon customers’ requests.

Sand casting and mold casting

Sand casting and mold castingThe sand casting line is equipped with an auto-molding machine in addition to mold-setting machines; therefore, we are capable of manufacturing from a single part to parts of relatively large lot size. We also have a cold box molding line and a self-hardening molding line so that the most suitable casting process can be chosen in accordance with the purposes of the products. The mold casting line is equipped with rotary casting machines and rotary cutting machines which are both developed and produced by us in order to save manpower in the production area. With these machines as the core of the line, we developed a consistent casting process by combining them with other automatic machines so as to reduce manufacturing cost and delivery lead-time.

■ Advantages

■ AdvantagesFrom aluminum casting prototype making to mass production speedily with optimum processes. You will be satisfied with our performance from the stages of drawing verification, prototype making, serial casting, machining, surface treatment including painting, assembling, checking, and to shipping.

■ Range of application

Automobiles, motorcycles, electric appliances, OA machinery, agricultural machinery, various machine tools

■ Processing accuracy

●Volume: 1 to 100,000 pcs./mon.

●Size: 10g to 100Kg

■ Material availability

Aluminum die casting:ADC3, ADC6, ADC12, ADC14, and others. (Zinc: Experiences in machining ZDC2 and BERIC)

Sand & die modling:AC2B, 4B, 4A, 4CV7A, AC4CH

【Company Profile】

【Company Profile】| ■ Company Name | : | Hikari Light Metals Co.,Ltd. |

| ■ Representative | : | CEO Mitsunobu Kokami |

| ■ Address | : | 〒709-0854 1050 Ejiri, Seto-cho, Higashi-ku, Okayama-shi, Okayama, Japan |

| ■ Establishment | : | 1944 |

| ■ Capital | : | 90 million yen |

| ■ Employees | : | 139 |

| ■ Major products | : | Sand molded and die molded parts, die cast parts, from proto making to serial production of aluminum wheel, from casting, machining, painting, and to finishing, from small lot to large lot |

| ■ Remarks | : | ISO9001 certified in 2001 ISO14001 certified in 2007 |

| ■ Web site URL | : | http://www.harenet.ne.jp/hikarikk/ |

|

Hikari Light Metals Co., Ltd. |

Major Equipment |